What Is Speed Lathe:

Introduction:

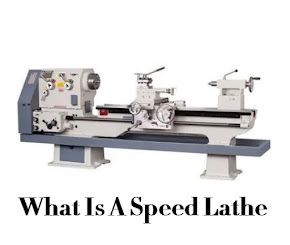

A speed lathe is a type of lathe machine that is designed to perform small and precise operations on a workpiece. It is also commonly referred to as a "bench lathe" or "engine lathe." Speed lathes are typically smaller in size and simpler in design compared to other types of lathes, and are primarily used for turning, drilling, and boring operations on small workpieces, such as metal rods or wooden dowels.

The main feature of a speed lathe is its ability to operate at very high speeds, which allows for quick and accurate machining of small parts. Speed lathes typically have a spindle speed range of several thousand revolutions per minute (RPM), and are powered by an electric motor. They also have a variety of cutting tools and attachments that can be used for different types of machining operations.

Speed lathes are commonly used in workshops, hobby shops, and educational settings, where they are used to teach basic machining skills and perform small-scale fabrication tasks.

Working Principle Of Speed Lathe:

The working principle of a speed lathe is based on rotating a workpiece against a cutting tool, in order to remove material and shape the workpiece.

Here are the basic steps involved in the operation of a speed lathe:

Mounting the workpiece:

The workpiece is mounted in a chuck or collet, which holds it securely in place while it rotates.

Selecting the cutting tool:

A variety of cutting tools can be used with a speed lathe, including turning tools, drills, and boring bars. The operator selects the appropriate tool for the job.

Adjusting the cutting tool:

The cutting tool is positioned and adjusted relative to the workpiece, so that it will remove material at the desired rate and depth.

Starting the lathe:

The lathe is started, and the workpiece begins to rotate. The operator then moves the cutting tool into contact with the workpiece, and begins to remove material.

Monitoring the cutting process:

The operator monitors the cutting process, adjusting the position and speed of the cutting tool as necessary, in order to achieve the desired dimensions and surface finish.

Stopping the lathe:

When the cutting operation is complete, the lathe is stopped and the workpiece is removed.

In a speed lathe, the workpiece is rotated at very high speeds, typically several thousand RPM, in order to achieve precise and rapid cutting. The cutting tool is manually controlled by the operator, who must have a good understanding of the principles of machining and the behavior of different materials in order to achieve the desired results.

Parts Of Speed Lathe:

Here are the main parts of a speed lathe:

Bed:

The bed is the main foundation of the lathe, and supports all the other components. It is usually made of cast iron, and has guide rails along which the other components can move.

Headstock:

The headstock is located at one end of the bed, and contains the spindle and motor that rotate the workpiece. It also has a chuck or collet that holds the workpiece in place.

Tailstock:

The tailstock is located at the opposite end of the bed, and is used to support and align the opposite end of the workpiece. It can be moved along the bed, and has a quill that can be extended to apply pressure to the workpiece.

Carriage:

The carriage is the main sliding component that moves along the guide rails on the bed. It contains the cutting tool, which can be adjusted in various ways to perform different cutting operations.

Cross-slide:

The cross-slide is a component of the carriage that moves perpendicular to the axis of the lathe, allowing the cutting tool to move across the workpiece.

Compound rest:

The compound rest is another component of the carriage that allows the cutting tool to be angled relative to the workpiece, allowing for more complex cuts and shapes.

Apron:

The apron is located beneath the carriage, and contains the mechanisms that control the movement of the carriage and cutting tool. It also has a feed rod that can be turned by hand to move the carriage along the bed.

Feed rod:

The feed rod is a component of the apron that can be turned by hand to move the carriage along the bed.

Lead screw:

The lead screw is a long, threaded rod that runs parallel to the bed, and is used to control the movement of the carriage and cutting tool automatically.

These are the main parts of a speed lathe, although there may be additional components depending on the specific design and features of the lathe.

Use Of Speed Lathe:

Speed lathes are commonly used for small-scale machining operations that require precision and accuracy. Here are some of the most common uses of a speed lathe:

Turning:

Speed lathes are often used for turning operations, in which a workpiece is rotated against a cutting tool to remove material and create a cylindrical shape. Turning can be used to create a variety of parts, such as shafts, pins, and bushings.

Drilling:

Speed lathes can also be used for drilling operations, in which a drill bit is rotated against a workpiece to create a hole. This is often used to create holes for fasteners or other components.

Boring:

Boring is a process in which a cylindrical hole is enlarged or smoothed out using a cutting tool. Speed lathes can be used for boring operations on small workpieces.

Polishing:

Speed lathes can be used for polishing or buffing operations, in which a polishing wheel is rotated against a workpiece to create a smooth surface finish.

Knurling:

Knurling is a process in which a pattern is pressed or cut into a workpiece to create a better grip surface. Speed lathes can be used for knurling operations on small workpieces.

Facing:

Facing is a process in which the end of a workpiece is flattened or smoothed out. Speed lathes can be used for facing operations on small workpieces.

Overall, speed lathes are useful for small-scale machining operations that require precision and accuracy. They are commonly used in machine shops, hobby shops, and educational settings for a wide variety of applications.

FAQs:

Here are some frequently asked questions (FAQs) about speed lathes:

What is the maximum size of a workpiece that can be handled by a speed lathe?

The maximum size of a workpiece that can be handled by a speed lathe varies depending on the specific model, but is generally smaller than larger, more complex lathes. Typically, speed lathes can handle workpieces up to 8 inches in diameter and 12 inches long.

What types of materials can be machined on a speed lathe?

Speed lathes can be used to machine a variety of materials, including metals, plastics, and wood. However, the type of material and the specific cutting operation will affect the speed and feed rates used on the lathe.

Can speed lathes be used for threading operations?

Yes, speed lathes can be used for threading operations, although they may require special tooling or attachments to do so. The lathe may also need to be equipped with a leadscrew and change gears to control the thread pitch.

Are speed lathes suitable for industrial production?

Speed lathes are generally not suitable for industrial production due to their limited capacity and manual operation. They are better suited for smaller-scale operations, such as hobby work or small-scale machine shops.

What safety precautions should be taken when using a speed lathe?

When using a speed lathe, it is important to wear appropriate personal protective equipment (PPE), such as safety glasses or a face shield. Loose clothing or jewelry should be avoided, and long hair should be tied back. The lathe should be properly grounded, and the workpiece should be securely clamped to avoid any movement during operation. The cutting tool should also be properly adjusted and maintained to prevent accidents or injuries.

0 Response to "What Is Speed Lathe ,Its working Principle and parts"

Post a Comment